How Can Businesses Ensure Supply Chain Resilience After a Major Disaster?

|

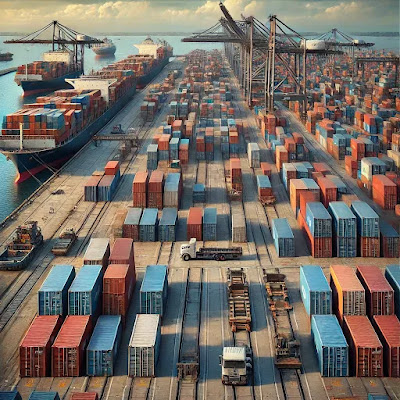

| image courtesy of chatGPT |

In the aftermath of a major disaster, maintaining a functional and resilient supply chain is critical for businesses to continue operations and serve their customers. Disruptions can come from various angles—natural disasters, infrastructure damage, or interruptions in supplier networks. To navigate these challenges, businesses need to adopt a range of strategies that not only address immediate needs but also fortify the supply chain against future disruptions.

Diversification of Suppliers

Relying on a single supplier or a single region can leave a business vulnerable when a disaster strikes. By establishing relationships with multiple suppliers across different geographical regions, businesses can reduce the risk of total supply chain collapse. For example, if a supplier in one region is affected by a hurricane or earthquake, alternative suppliers in unaffected regions can step in to fill the gap. This diversification is crucial for maintaining the flow of essential materials or components.

Inventory Management

Maintaining higher levels of critical inventory, also known as safety stock, provides a buffer during supply chain interruptions. This is especially important for items that are difficult to source or take longer to produce. While excess inventory can tie up capital and increase storage costs, the trade-off is often worth it when disaster strikes, ensuring that businesses have enough stock on hand to meet customer demand without waiting for disrupted suppliers to recover.

Local Sourcing

Shifting from global to more localized or regional sourcing can also improve supply chain agility in times of crisis. Local suppliers are generally less affected by international shipping delays or port closures. By reducing dependency on distant suppliers, businesses can respond more quickly to disruptions and maintain operational continuity. Additionally, local sourcing reduces the risk of political or economic instability affecting global supply chains.

Digital Transformation

The integration of advanced digital tools into supply chain operations can dramatically enhance resilience. Technologies such as artificial intelligence (AI) and machine learning enable real-time monitoring and predictive analytics, helping businesses identify potential risks before they escalate. For instance, AI can track weather patterns, transportation issues, or geopolitical risks that may impact suppliers, allowing businesses to adjust their strategies proactively. Digital tools also improve visibility across the entire supply chain, from raw materials to finished products, helping businesses make faster, more informed decisions during a crisis.

Business Continuity Plans (BCP)

A robust Business Continuity Plan is essential for any company looking to ensure supply chain resilience during a disaster. BCPs should outline specific procedures for maintaining operations, including alternative supply routes, backup suppliers, and emergency communication protocols. Regular updates to these plans ensure they remain relevant in a rapidly changing business environment. Companies should also conduct regular drills and simulations to test the effectiveness of their BCPs, ensuring that employees and suppliers know how to respond when disaster strikes.

Supplier Collaboration

Collaboration with suppliers is key to ensuring their disaster preparedness aligns with your own. Businesses should work closely with their suppliers to confirm that they have their own disaster recovery plans in place. Maintaining open communication channels ensures that businesses receive timely updates on any issues affecting supplier operations, allowing for quicker adjustments. Strong supplier relationships also create a sense of partnership, encouraging suppliers to prioritize your business during a disruption.

Reshoring and Nearshoring

For companies heavily dependent on international suppliers, reshoring or nearshoring production closer to the end consumer can mitigate risks related to long-distance transportation. This approach not only reduces the time and cost involved in shipping but also minimizes exposure to risks like port closures, border issues, or international conflict. Moving production to the same region or country where the business operates allows for more reliable and faster response times in the event of a disruption.

Regular Risk Assessments

Ongoing risk assessments are essential for identifying new vulnerabilities in the supply chain. Conducting these assessments regularly ensures that businesses stay ahead of potential risks and can address them proactively. For instance, assessments may reveal dependencies on a single raw material or supplier, prompting businesses to diversify or strengthen relationships with alternative suppliers. By staying vigilant, businesses can minimize the impact of future disruptions.

Conclusion

By implementing these strategies—diversifying suppliers, improving inventory management, embracing local sourcing, leveraging digital tools, collaborating with suppliers, and conducting regular risk assessments—businesses can significantly enhance their supply chain resilience. In the face of a disaster, a well-prepared supply chain ensures operational continuity and positions the business to recover quickly, serving customers with minimal disruption. Planning today for tomorrow's uncertainties is key to long-term success.

Source: Conversation with Copilot, 9/26/2024

No comments:

Post a Comment